It is essential to provide sufficient and appropriate ventilation in businesses, plants and factories. In the industrial sector, maintaining optimal air quality and temperature is critical not only for the health and safety of workers, but also for the efficiency of manufacturing processes.

The Prana industrial ventilation/ decentralised MVHR can handle all the challenges. The system ensures fresh, clean air at all times, removes pollutants and guarantees a healthy microclimate in production facilities.

Local exhaust ventilation system for your Factory

Benefits of using The Prana industrial ventilation systems / decentralised MVHR:

- Energy Efficiency. One of the most significant advantages of these systems is their ability to reduce energy consumption. By reusing heat from exhaust air, factories can decrease the need for additional heating or cooling, leading to substantial energy savings.

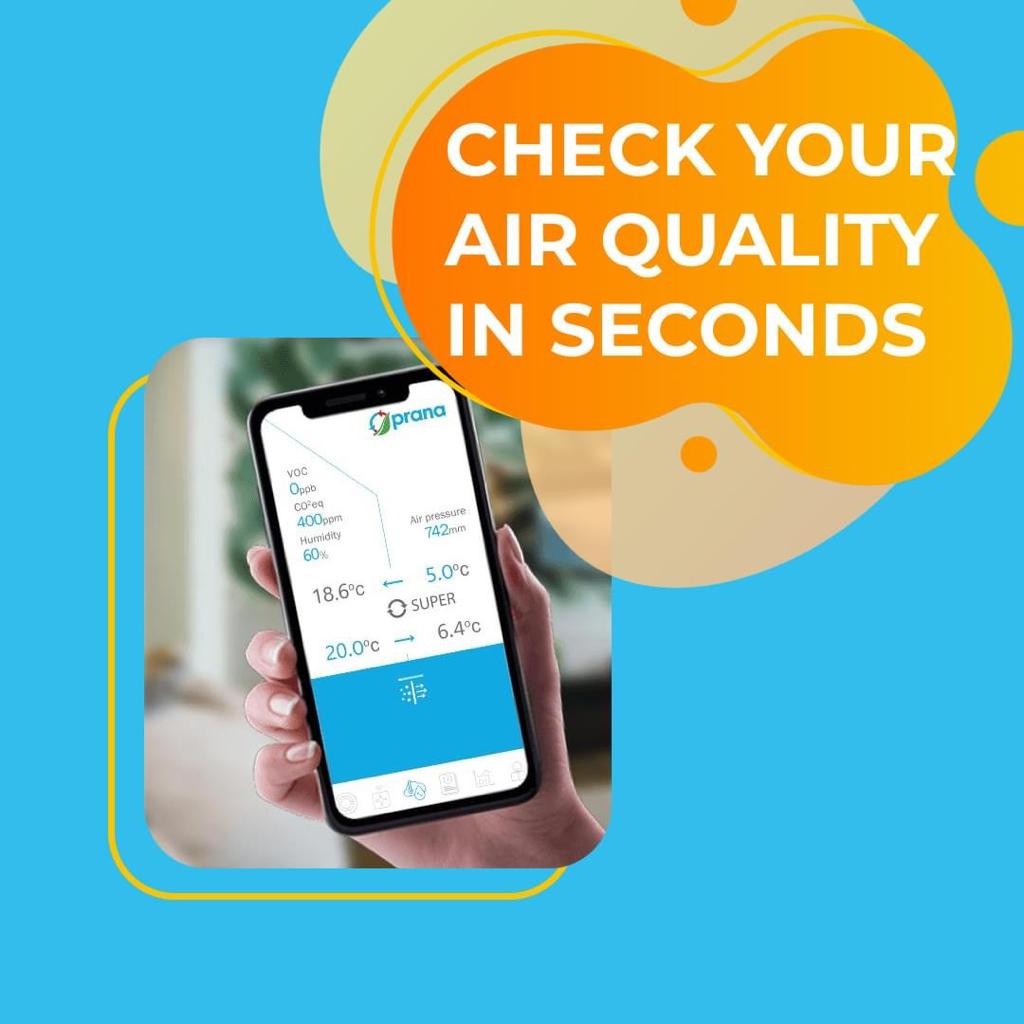

- Improved Air Quality. These systems ensure a consistent supply of fresh air, crucial in factories where pollutants, chemicals, and particulates are often present.

- Cost-Effective Operation. Despite the initial investment, the long-term reduction in energy costs makes these systems a cost-effective solution for industrial spaces.

- Enhanced Worker Safety and Comfort. Maintaining a stable indoor temperature and reducing airborne contaminants contribute to a safer and more comfortable working environment.

- Environmental Responsibility: Reduced energy consumption translates to a lower carbon footprint, aligning with sustainability goals.

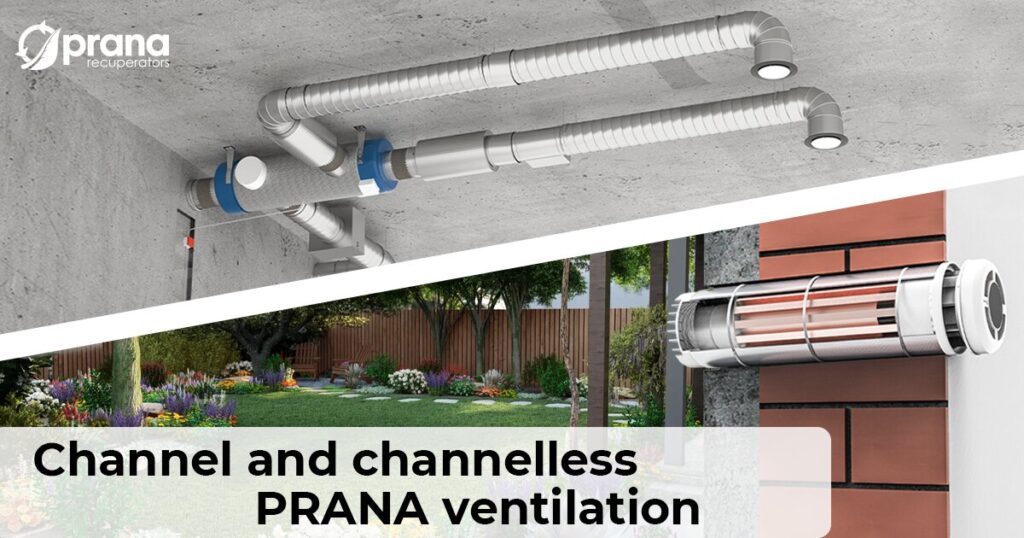

How does industrial ventilation system/ decentralised MVHR work?

Factory ventilation systems with heat recovery units are designed to provide a continuous supply of fresh air while conserving energy. These systems work by extracting stale, contaminated air from the factory space and simultaneously introducing fresh outside air. The key component, the heat exchanger, transfers heat from the outgoing air to the incoming air, conserving energy that would otherwise be lost.

Local exhaust ventilation systems in factories

Local exhaust ventilation (LEV) systems are specifically designed to remove contaminants at the source before they can disperse into the factory air. These systems are essential in processes that emit dust, fumes, vapours or gases, effectively protecting workers from harmful exposure.